Metal Decking Sheets

Price 30 INR/ Square Meter

Metal Decking Sheets Specification

- Standard

- IS 2062, ASTM A653

- Shape

- Trapezoidal, Ribbed

- Surface Treatment

- Galvanized, Painted, Coated

- Process

- Profiled, Pre-engineered

- Temper

- Customized as per requirement

- Material

- Galvanized Steel, Mild Steel

- Type

- Roof Deck, Floor Deck

- Technique

- Cold Rolled, Roll Forming

- Thickness

- 0.80 mm to 2.00 mm

- Application

- Industrial buildings, commercial structures, residential flooring, mezzanine floors

- Feature

- High strength, corrosion resistance, durable, lightweight, easy installation

- Width

- 600 mm to 1200 mm

- Profile Depth

- 45 mm to 75 mm

- Packaging Type

- Bundle

- Coating Thickness

- 80 GSM to 275 GSM

- Color Options

- Blue, Grey, Customized

- Installation Method

- Screw fastened/ welded

- Yield Strength

- 245 MPa to 350 MPa

- Length

- Custom length available

- Fire Resistance

- Good

Metal Decking Sheets Trade Information

- Minimum Order Quantity

- 1000 Square Meters

- Supply Ability

- 20000 Square Meters Per Week

- Delivery Time

- 2-5 Days

About Metal Decking Sheets

Being a customer-focused organization, we are engaged in offering Metal Decking Sheets. Trapezoidal Metal Profile sheets with strong and reliable shear bond performance which is augmented by cross embossing located in the profile. The composite floor profile offers the ultimate in the light weight steel decking which reduced concrete usage to provide a cost effective and alternative floor solution that easy to install.

Applications:

- High Rise Buildings

- Multiplexes/Commercial Buildings

- Power Plant Buildings

- Office Buildings

- Mezzanine Floors in Industrial Buildings & Warehouses

- Steel floor deck for mezzanine floors

- Cold Rolled (CR)

- Galvanized

- Reduced Concrete usage: Tensile steel for composite slab construction that cuts down on slab thickness and dead weight of buildings. Providing a more sustainable solution and reducing costs

- No separate form work required for slab casting

- Reduces construction time

- 0.8 mm/1 mm/1.2 mm

Product details

| Shape | Rectangular |

| Thickness | 0.8 mm/1 mm/1.2 mm |

| Material | SS, MS |

| Surface Treatment | Galvanised |

| Technique | Cold Rolled |

| Length | 4-8 m |

| Features | Water Proof |

Customizable Dimensions for Flexible Application

Metal Decking Sheets are available in widths from 600 mm to 1200 mm, with profiles in depths ranging from 45 mm to 75 mm. Their length can be precisely tailored to fit specific project requirements, making them suitable for a wide array of construction needsfrom residential flooring to industrial buildings. Each sheet delivers robust performance and effortless integration into architectural designs.

High Strength and Durable Protection

These sheets are manufactured using high-yield strength materials (245 MPa to 350 MPa), ensuring they can support heavy loads and maintain integrity under stress. With coating thicknesses ranging from 80 GSM to 275 GSM and options for galvanized, painted, or coated surfaces, the decking is designed to resist corrosion and provide lasting protection against the elements.

Efficient Installation and Versatile Usage

Installation is simplified with either screw fastening or welding methods. This flexibility, combined with their lightweight structure, streamlines site logistics and speeds up the build process. Suitable for roof decks, floor decks, and mezzanine floors, these sheets adapt easily to various construction environments, enhancing both safety and operational efficiency.

FAQs of Metal Decking Sheets:

Q: How are metal decking sheets installed on site?

A: Metal decking sheets are typically installed using screw fasteners or welding methods, which ensures a secure connection to the structural framework. The installation process is straightforward due to the lightweight nature of the sheets, reducing labor effort and minimizing project timelines.Q: What advantages do metal decking sheets offer over traditional flooring solutions?

A: Metal decking sheets provide higher yield strength (245 MPa to 350 MPa), superior corrosion resistance, and enhanced durability. Their lightweight design facilitates easier transportation and installation, while customizable profiles and coating options ensure longevity and adaptability to various construction requirements.Q: When should metal decking sheets be used in construction projects?

A: Metal decking sheets are ideal for use in industrial buildings, commercial structures, residential flooring, and mezzanine floors where structural strength, speed of installation, and durability are essential. Their fire resistance and versatile profiles make them suitable for environments with demanding safety and load-bearing needs.Q: Where can these decking sheets be applied?

A: These sheets are suitable for a range of horizontal and roofing applications, including industrial and commercial buildings, mezzanine floors, warehouses, workshops, and residential construction, thanks to their customizable dimensions and robust performance.Q: What process is followed for manufacturing metal decking sheets?

A: Metal decking sheets are produced using cold rolling and roll forming techniques, followed by surface treatment steps such as galvanizing, painting, or coating. Profiling is done as per design requirements to achieve trapezoidal or ribbed shapes, and temper can be customized to match specific project needs.Q: How does the coating thickness affect the performance of metal decking sheets?

A: A higher coating thickness, ranging from 80 GSM to 275 GSM, enhances the corrosion resistance of metal decking sheets, making them more durable against environmental factors. This protective layer ensures extended lifespan and reduced maintenance in harsh conditions.Q: What material and standards do these sheets comply with?

A: Metal decking sheets are available in galvanized steel, mild steel, or other specified materials, and they adhere to recognized standards such as IS 2062 and ASTM A653, ensuring quality, safety, and consistent performance in construction applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Metal Sheet Category

Color Coated Metal Roofing Sheet

Price 30 INR / Square Meter

Minimum Order Quantity : 1000 Square Meters

Type : Color Coated Metal Roofing Sheet

Technique : Cold Rolled

Thickness : 0.35 mm to 0.80 mm

Process : Roll Forming

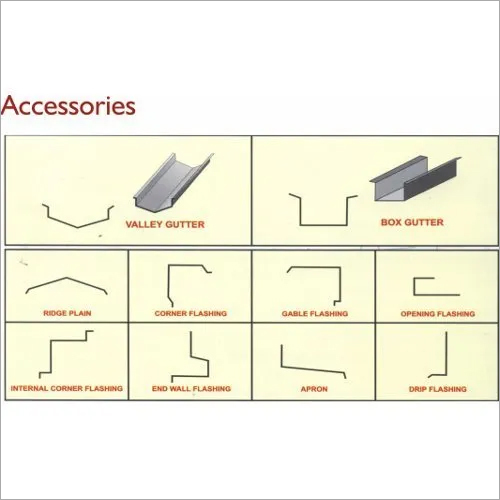

Roofing Accessories

Price 30 INR / Square Meter

Minimum Order Quantity : 1000 Square Meters

Type : Roofing Accessories

Technique : Cold Rolled

Thickness : 0.40 mm 1.2 mm

Process : Roll Forming

Metal Tile Roofing

Price 30 INR / Square Meter

Minimum Order Quantity : 1000 Square Meters

Type : Metal Tile Roofing

Technique : Cold Rolled

Thickness : 0.40 mm

Process : Pressed Forming

Pre Painted Aluminum Zinc Alloy Coated Steel

Price 30 INR / Square Meter

Minimum Order Quantity : 1000 Square Meters

Type : Coil / Sheet

Technique : Cold Rolled

Thickness : 0.13 mm 1.2 mm

Process : Continuous Hot Dip Coating & Pre Painting

Send Inquiry

Send Inquiry