Pre Painted Aluminum Zinc Alloy Coated Steel

Price 30 INR/ Square Meter

Pre Painted Aluminum Zinc Alloy Coated Steel Specification

- Process

- Continuous Hot Dip Coating & Pre Painting

- Surface Treatment

- Pre Painted / Color Coated

- Temper

- Soft, Hard, Half Hard

- Standard

- JIS G3322, ASTM A792, EN 10346

- Shape

- Flat, Coil

- Material

- Aluminum-Zinc Alloy Coated Steel

- Type

- Coil / Sheet

- Technique

- Cold Rolled

- Thickness

- 0.13 mm - 1.2 mm

- Application

- Construction, Automotive, Home appliances, Roofing, Wall panels

- Feature

- High corrosion resistance, Smooth finish, Long durability

- Paint Coating Thickness

- 15-20 micron (Top) / 5-7 micron (Back)

- Width Range

- 600 mm to 1250 mm

- Packing

- Standard Export Seaworthy Packing

- Adhesion Test

- Passes T-bend and Pencil Hardness

- Yield Strength

- 240-550 MPa

- Environment Compatibility

- Lead free, RoHS compliant

- Roll Weight

- 2-8 MT

- Elongation

- 18-28%

- Service Life

- Up to 25 years (depending on environment)

- Color Options

- RAL standard colors, Custom colors available

- Coating Mass

- AZ50 to AZ150

Pre Painted Aluminum Zinc Alloy Coated Steel Trade Information

- Minimum Order Quantity

- 1000 Square Meters

- Supply Ability

- 20000 Square Meters Per Week

- Delivery Time

- 2-5 Days

About Pre Painted Aluminum Zinc Alloy Coated Steel

We are Leading Supplier, Trader, Distributor & Dealer of Pre-Painted Aluminum - Zinc Alloy Coated Steel (PPGL) in Chennai, TamilNadu & South India Majorly. that is manufactured under advanced technologies and high supervision in order to deliver the best possible steel. This combination of elements and thickness makes it the perfect choice for your applications, due to its high tensile strength.Technical specifications:

| Base metal | high tensile steel |

| Combination | 55% aluminum, 434% zinc & 1. 6% silicon |

| Thickness | 0. 47mm-0. 50mm |

| Tensile strength | 550mpa |

| Zinc coating | z150 |

| Type of coating | regular modified polyester |

| Painting thickness (top) | 18-20microns |

| Painting thickness (bottom) | 5-7microns |

| Tolerance | ±0. 03mm |

Dimensions:

| Profile | profiled sheet width | profiled effective width |

| Trapezoidal roofing | 1060mm | 1000mm |

High Performance Coating for Lasting Protection

Utilizing advanced continuous hot dip coating and pre-painting technology, our pre painted aluminum zinc alloy steel delivers a tough, weather-resistant finish. The combination of aluminum and zinc enhances corrosion resistance, making this product robust for exterior and interior use in diverse industries. Its service life can reach up to 25 years, even in challenging environments.

Versatile and Customizable for Every Application

This steel is offered in a variety of thicknesses, widths, and coil weights to accommodate project needs. Whether you require a flat, sheet, or coil form, and from soft to hard temper, the options ensure flexibility in design and application. The availability of RAL standard and custom colors further allows for unique aesthetic solutions in construction, automotive, and home appliances.

Environmentally Friendly and Safe

Our product meets modern environmental standards, being fully RoHS compliant and lead-free. This ensures safety for both users and end applications. With smooth finishes and quality assurance through international standards like JIS G3322, ASTM A792, and EN 10346, you can trust in both the performance and sustainability of this coated steel.

FAQs of Pre Painted Aluminum Zinc Alloy Coated Steel:

Q: How is pre painted aluminum zinc alloy coated steel manufactured?

A: This steel is produced using a continuous hot dip coating process, where a steel substrate is coated with an aluminum-zinc alloy for enhanced corrosion resistance. It is then pre-painted to deliver the final color and finish, ensuring durability and a uniform appearance.Q: What are the main benefits of using this type of coated steel?

A: Key benefits include high corrosion resistance, a smooth and durable painted finish, flexibility in color choices, and long service life of up to 25 years. Additionally, it is environmentally friendly, being both lead-free and RoHS compliant.Q: Where can this product be used effectively?

A: It is designed for a range of applications including construction (roofing, wall panels), home appliances, the automotive sector, and exterior or interior building cladding. Its high durability and versatile form make it suitable for numerous industries.Q: What color options are available for the coated steel?

A: Customers can select from RAL standard color options, or request custom colors tailored to their specific requirements, making it ideal for projects with unique design specifications.Q: What is the recommended thickness and width range for various applications?

A: Thickness ranges from 0.13 mm to 1.2 mm and widths from 600 mm to 1250 mm. Thicker products are generally preferred for structural and roofing applications, while thinner materials may be suited for appliances and interior uses.Q: How is the product packaged for shipment?

A: The pre painted aluminum zinc alloy coated steel is packed using standard export seaworthy packing to protect coils or sheets during transportation, ensuring they arrive in optimal condition for use at the destination.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Metal Sheet Category

Color Coated Metal Roofing Sheet

Price 30 INR / Square Meter

Minimum Order Quantity : 1000 Square Meters

Temper : As per requirement

Standard : ASTM/IS/JS/EN

Shape : Trapezoidal, Wave, Curved

Type : Color Coated Metal Roofing Sheet

Metal Tile Roofing

Price 30 INR / Square Meter

Minimum Order Quantity : 1000 Square Meters

Temper : Soft

Standard : ASTM / IS Standard

Shape : Tile Shaped

Type : Metal Tile Roofing

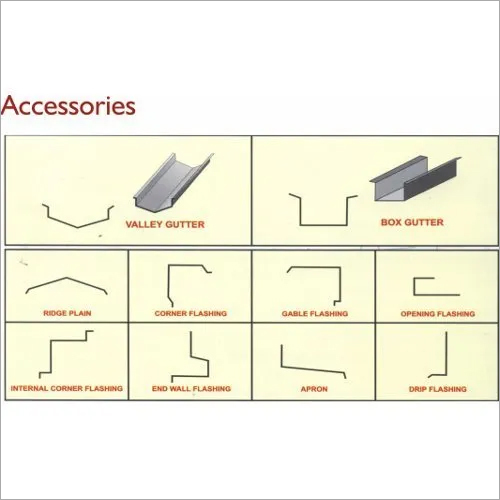

Roofing Accessories

Price 30 INR / Square Meter

Minimum Order Quantity : 1000 Square Meters

Temper : Soft, Half Hard, Hard

Standard : IS 277, ASTM A653

Shape : Rectangular, Corrugated, Trapezoidal

Type : Roofing Accessories

Bare Galvalume Sheets

Price 30 INR / Square Meter

Minimum Order Quantity : 1000 Square Meters

Temper : Soft/Annealed

Standard : ASTM A792/A792M

Shape : Sheet

Type : Bare Galvalume Sheet

Send Inquiry

Send Inquiry