Lexan Compact Sheet

Price 30 INR/ Square Meter

Lexan Compact Sheet Specification

- Roof Material

- Polycarbonate Lexan

- Height

- Sheet format; not applicable for height

- Usage & Applications

- Roof glazing, skylights, partitions, safety glazing, signage, canopies

- Surface Treatment

- UV Protected on one/both sides

- Features

- Light transmission up to 90%

- Technics

- Extruded

- Material

- Polycarbonate (Lexan)

- Tile Material

- Polycarbonate

- Tile Type

- Compact Sheet

- Type

- Solid/Flat Sheet

- Size

- Standard and custom sizes available; typical width up to 2.1 meters

- Shape

- Rectangular

- Pattern

- Clear/Transparent

- Heat Transfer Coefficient

- 2.1-3.9 W/mK (depending on thickness)

- Thickness

- 1 mm to 12 mm

- Length

- Customized (Standard coils or sheets, typically up to 30 meters for thin gauge)

- Width

- Up to 2100 mm

- Color Options

- Clear, Bronze, Green, Blue, Opal, Custom colors

- Edge Treatment

- Protective film on both sides as supplied

- Weight

- 1.2 kg/m² per mm thickness

- Chemical Resistance

- Good resistance to many chemicals and solvents

- Specific Gravity

- 1.2 g/cm³

- Temperature Resistance

- -40°C to +120°C

- Impact Strength

- 250 times stronger than glass of equal thickness

- Fire Rating

- Class B1 (EU); compliant with EN 13501-1

- Light Transmission

- Up to 90% depending on thickness and color

Lexan Compact Sheet Trade Information

- Minimum Order Quantity

- 1000 Square Meters

- Supply Ability

- 20000 Square Meters Per Week

- Delivery Time

- 2-5 Days

- Main Domestic Market

- South India

About Lexan Compact Sheet

We are a well-known organization engaged in offering Lexan Compact Sheet. These sheets are manufactured using high-grade raw material and advanced machines to remain in tandem with international standards and norms. Clients can avail these sheets in various unique designs, sizes, carvings and shapes as per their requirements.

Technical Properties:

- Excellent weathering property

- Excellent light transmission ranging from 40% to 90%

- Both side UV coated

Commercial Applications:

- Residence / commercial building skylight

- Sport stadium skylight

- Sound barrier

- Hospitals

- Interior partition

- Industrial application

- Signage application (opal white)

- Signage lamp box

- Bulletin

- Out-door signage board

Colors Available:

- Transparent

- Bronze

- Opal white

- Custom made colors

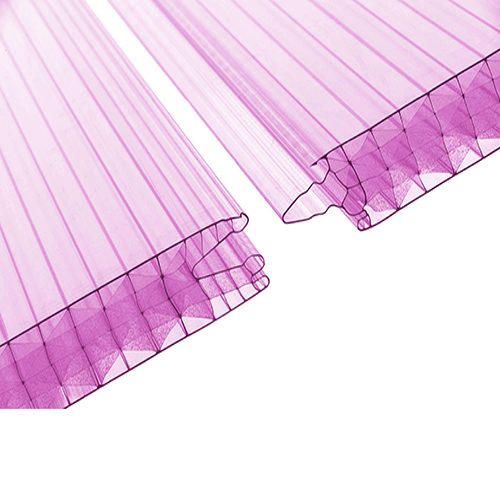

Thickness:

-

1.0 mm/1.5 mm/1.7 mm/2.0 mm/3.0 mm/4.0 mm to 10.0 mm

Sizes:

- Width: 900 mm/1220 mm/2050 mm

- Length: 2440 mm/15250 mm/30500 mm

Technical Specifications

| Brand | SRE |

| Technique | Clear Glass |

| Thickness(mm) | 1mm,2mm,3mm |

| Dimensions | Customized |

| Surface Treatment | Galvanised,Coated,Film Coated,Embossed |

| Color | Blue |

Exceptional Light Transmission and Strength

Lexan Compact Sheet stands out with its remarkable transparency and light transmission, reaching up to 90% based on thickness and color. Its polycarbonate construction ensures incredible durability, boasting an impact resistance 250 times greater than glass. This blend of clarity and toughness makes it perfect for architectural and safety applications where reliable performance is essential.

Versatile Color and Size Options

With a palette spanning clear, bronze, green, blue, opal, and custom colors, Lexan Compact Sheet adapts seamlessly to diverse design requirements. Sizes and thicknesses cater to both standard needs and bespoke projects, with widths up to 2.1 meters and custom lengths available. UV protection on one or both sides further enhances adaptability for both indoor and outdoor settings.

FAQs of Lexan Compact Sheet:

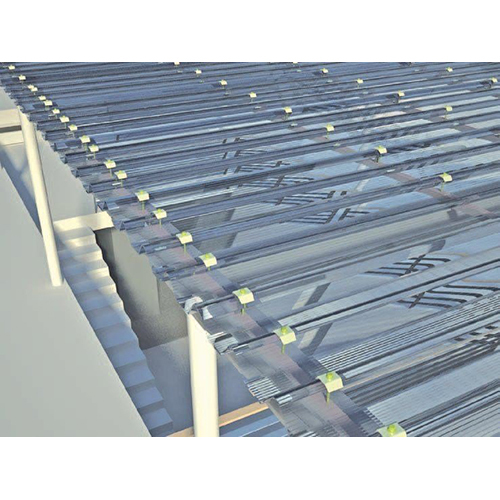

Q: How is Lexan Compact Sheet installed for roofing and glazing applications?

A: Lexan Compact Sheet is typically cut to size and fitted using conventional glazing channels or frames. Its flexibility and lightweight nature facilitate straightforward handling and installation for roofing, skylights, and architectural partitions, requiring minimal specialized tools.Q: What benefits does Lexan Compact Sheet offer compared to traditional glass?

A: The sheet provides significantly greater impact strength250 times stronger than glassalongside lighter weight, superior chemical resistance, and higher light transmission rates. It also offers better thermal insulation and is much safer in high-security or hazardous environments.Q: When should custom colors or sizes be selected for a project?

A: Custom colors and sizes are ideal when design specifications require a specific appearance or when standard sheet dimensions do not fit the intended application. This flexibility allows architects and builders to meet aesthetic or structural needs precisely.Q: Where can Lexan Compact Sheets be used effectively?

A: These sheets are widely used in roof glazing, skylights, safety glazing, partitions, signage, and canopies. Their robust construction and UV protection make them suitable for a variety of commercial, industrial, and residential settings within India or worldwide.Q: What process ensures Lexan Compact Sheets durability and UV resistance?

A: During manufacturing, the polycarbonate material is extruded and a protective UV coating is applied to one or both sides. This process safeguards against discoloration, degradation, and maintains long-term clarity and structural integrity under sun exposure.Q: How does the fire rating of Lexan Compact Sheet support safety compliance?

A: Lexan Compact Sheet holds a Class B1 fire rating under European standard EN 13501-1, ensuring it is compliant with relevant safety regulations. This certification confirms its suitability for use in environments where fire safety is crucial.Q: What maintenance is required to preserve Lexan Compact Sheet performance?

A: Routine cleaning with mild soap and water is sufficient for maintaining clarity. Avoid harsh chemicals or abrasive materials, and ensure the protective film is removed only after installation to preserve the sheets surface quality during handling.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Polycarbonate Sheet Category

Lexan Margard Sheet

Material : Other, Polycarbonate (PC)

Size : Standard/Custom (commonly 8ft x 4ft or as required)

Tile Type : Other, Solid Sheet

Type : Lexan Margard Sheet

Width : Up to 2100 mm (custom widths available)

Length : Up to 1220 mm x 2440 mm per standard sheet (custom lengths available)

Thermoclick Sheet

Material : Other, Polycarbonate

Size : Customizable

Tile Type : Thermoclick, Other

Type : Roofing Sheet

Width : 1 meter

Length : 5 meters

Lexan Thermoclick Sheet

Material : Other, Polycarbonate

Size : Customizable

Tile Type : Thermal Insulating Sheet, Other

Type : Building Sheet

Width : 500 mm

Length : 6000 mm

Aero Probubble Guards

Material : Plastic, Other

Size : Customizable

Tile Type : Other, Guard Tile

Type : Aero Probubble Guards

Width : Standard

Length : Standard

Send Inquiry

Send Inquiry