Lexan Margard Sheet

Price 30 INR/ Square Meter

Lexan Margard Sheet Specification

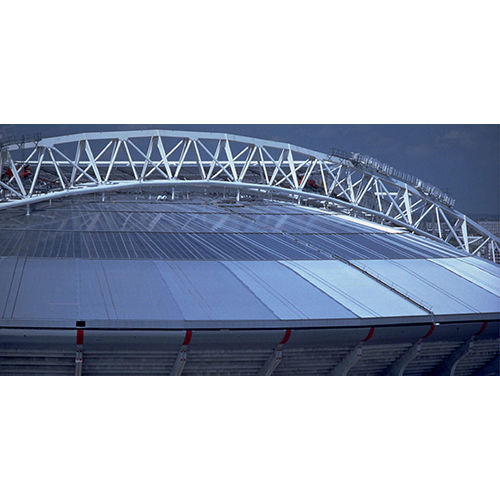

- Roof Material

- Polycarbonate Sheet

- Features

- High impact strength, UV resistance, optical clarity, abrasion resistance, easy to fabricate, chemical resistance

- Height

- As per sheets and application (not typically specified as height)

- Usage & Applications

- Security glazing, machine guards, protective shields, architectural glazing, transportation windows, riot shields, safety glazing

- Technics

- Extruded, hard coated

- Surface Treatment

- Margard hard coating on one or both sides for scratch and chemical resistance

- Material

- Polycarbonate (PC)

- Tile Material

- Polycarbonate

- Tile Type

- Solid Sheet

- Type

- Lexan Margard Sheet

- Size

- Standard/Custom (commonly 8ft x 4ft or as required)

- Shape

- Rectangular

- Pattern

- Plain / Smooth

- Heat Transfer Coefficient

- ~5.7 W/mK (approximate)

- Thickness

- Available from 1.5 mm to 12 mm (commonly used: 3 mm, 4.5 mm, 6 mm, 12 mm)

- Length

- Up to 1220 mm x 2440 mm per standard sheet (custom lengths available)

- Width

- Up to 2100 mm (custom widths available)

- Tensile Strength

- Approx. 60 MPa

- Light Transmission

- Up to 86% (depending on thickness)

- Color

- Clear (standard), custom tints available

- Density

- Approx. 1.2 g/cm

- Service Temperature Range

- -40C to +120C

- Impact Strength

- 250-300 times greater than glass of same thickness

- Edge Finish

- Saw cut or polished

- Fire Rating

- UL94 V-2 (self-extinguishing)

Lexan Margard Sheet Trade Information

- Minimum Order Quantity

- 1000 Square Meters

- Supply Ability

- 20000 Square Meters Per Week

- Delivery Time

- 2-5 Days

About Lexan Margard Sheet

We are a renowned firm engaged in offering Lexan Margard Sheet, which is procured from the top notch raw material procured from the reliable vendors of the market. Fabrication with layers of polycarbonate and sufficient quantities of heat and pressure is required to manufacture these sheets in compliance with set industry standards. Clients can avail these sheets in various models and colors as per their requirements.

Properties:

- Silicon hard coating sheet abrasion resistant

- Optical property

- Both side UV coated

Applications:

- Bank cash counters & ATM

- Armored vehicle

- Safety helmet & visors

- Railway windows and drivers look-out glass

Colors:

- Clear

- Bronze

Thickness & Sizes:

- 3.0 mm to 6.0 mm

- 1220 x 2440 mm, 2000 x 3000 mm

Product details

| Size | 1220 x 2440 mm,2000 x 3000 mm |

| Surface Treatment | Film Coated |

| Material | Lexan |

| Thickness(mm) | 3mm to 6 mm |

| Features | Water Proof,Tamper Proof |

| Transparency | 40-90 % |

Exceptional Strength and Safety

Lexan Margard Sheet delivers impact resistance far superior to traditional glass, making it a preferred choice for situations demanding robust safety and durability. Its self-extinguishing UL94 V-2 fire rating adds an extra layer of security wherever it is used.

Optical Clarity with Light Transmission

With light transmission reaching up to 86%, depending on thickness, this sheet offers remarkable transparency for architectural glazing, protective shields, or transportation windows. The clear and smooth surface ensures unobstructed visibility and aesthetic appeal.

Versatile Sizes and Easy Fabrication

Available in standard sizes up to 1220 mm x 2440 mm and custom dimensions, Lexan Margard Sheets can be fabricated to meet diverse design requirements. They are easily cut, edged, and shaped, enabling seamless integration into projects of all types.

FAQs of Lexan Margard Sheet:

Q: How does Lexan Margard Sheet compare to glass in terms of impact resistance?

A: Lexan Margard Sheet provides impact strength 250-300 times greater than glass of the same thickness, dramatically reducing the risk of breakage and improving safety in demanding environments.Q: What applications are ideal for using Lexan Margard Sheets?

A: These polycarbonate sheets are commonly used for security glazing, protective shields, architectural panels, machine guards, transportation windows, riot shields, and safety glazing due to their durability and clarity.Q: What benefit does the Margard hard coating offer?

A: The Margard hard coating gives the sheet superior scratch and chemical resistance, ensuring longer-lasting optical clarity and maintaining the appearance even in challenging conditions.Q: Can Lexan Margard Sheets be customized in size, color, or thickness?

A: Yes, besides standard clear sheets, custom tints, thicknesses (from 1.5 mm to 12 mm), and dimensions (up to 2100 mm wide and 2440 mm long) can be tailored to project specifications.Q: Where are Lexan Margard Sheets typically installed?

A: They are installed in locations requiring robust safety and transparency, such as commercial buildings, transportation vehicles, factories, and public spaces for both protective and aesthetic functions.Q: What is the process for fabricating and installing these sheets?

A: Lexan Margard Sheets can be easily cut, edged (saw cut or polished), and shaped by extrusion. Installation is straightforward for both standard and custom sizes, adapting to various structures and frames.Q: When is it recommended to use this sheet over other materials?

A: Choose Lexan Margard Sheet when high impact strength, optical clarity, UV resistance, and fire safety are criticalespecially in environments prone to physical stress or risk of breakage.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Polycarbonate Sheet Category

Lexan Polycarbonate Sheet

Price 30 INR / Square Meter

Minimum Order Quantity : 1000 Square Meters

Shape : Rectangular

Thickness : 1 mm to 12 mm

Width : up to 2100 mm

Pattern : Plain/Clear

Lexan Thermoclear Multiwall Sheet

Price 30 INR / Square Meter

Minimum Order Quantity : 1000 Square Meters

Shape : Rectangular

Thickness : 4mm, 6mm, 8mm, 10mm, 16mm, 20mm

Width : 2100 mm

Pattern : Multiwall Structure

Lexan Multiwall Sheet

Shape : Rectangular

Thickness : 4mm, 6mm, 8mm, 10mm, 16mm (Varies by product)

Width : 1.05m, 1.22m, 2.1m (Varies by model)

Pattern : Multiwall (Cellular)

Matching Roof Profile Sheet

Shape : Flat

Thickness : Varies (e.g. 2mm 4mm etc.)

Width : Customizable

Pattern : Transparent

Send Inquiry

Send Inquiry