Metal Sheet Insulated Panels

Price 30 INR/ Square Meter

Metal Sheet Insulated Panels Specification

- Product Type

- Metal Sheet Insulated Panel

- Material

- Pre-painted galvanized steel sheet with polyurethane or polyisocyanurate foam core

- Usage

- Thermal and acoustic insulation for buildings

- Application

- Roofing and wall cladding in industrial, commercial, and residential structures

- Size

- Standard thickness: 30mm to 100mm; Width: 1000mm (customizable)

- Weight

- Approx. 10-15 kg/m2 depending on thickness

- Color

- Blue, Grey, White, Customized

- Tensile Strength

- 240-550 MPa depending on material grade

- Capacity

- High load-bearing capacity, suitable for structural use

- Feature

- Fire-resistant, weatherproof, easy installation, maintenance-free

- Fire Rating

- Class A/B as per international standards

- Corrosion Resistance

- High, due to galvanized and coated surface

- Thermal Conductivity

- 0.022-0.026 W/mK (PU core)

- Joint Type

- Tongue and groove/overlap joint

- Core Density

- 38-42 kg/m3 (PU)

- Sound Insulation

- Excellent acoustic attenuation properties

- Temperature Resistance

- -40C to +80C

- Surface Coating

- Polyester/PPGL/PPGI coating available

- Panel Length

- Up to 12000mm (customized as required)

- Surface Finishes

- Smooth, corrugated, or embossed finishes available

- Water Absorption

- <2% (by volume)

Metal Sheet Insulated Panels Trade Information

- Minimum Order Quantity

- 1000 Square Meters

- Supply Ability

- 20000 Square Meters Per Week

- Delivery Time

- 2-5 Days

- Main Domestic Market

- South India

About Metal Sheet Insulated Panels

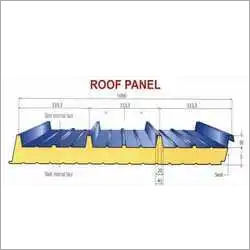

Metal Sheet Insulated Panels are highly sophisticated building products, produced with profiled Pre-Painted Zinc Coated/Galvalume Coated Steel and combined with Polyurethane as the insulation material. These products are available in Roof Panel System and Wall Panel System.

With a wide range of different colors, cut-to-length and supplied ready-to-install, our modern building products will take a good share in a highly economic, weather-independent and fast, modular building process.

Properties:

- High Thermal & Mechanical Resistance

- Dimensional Stability & Fire retardant

- Non water absorbent & Light weight

- Aesthetically pleasing Appearance

- Durability

- Ease and Speed of Installation

Applications:

- Large warehouses

- General Food processing Industry

- Pharmaceutical Industry

- Partition Walls

- Cladding

Thickness:

- Foam Density 40 kg/m3

- Sheet thickness Top 0.40 to 0.50 mm

- Sheet thickness Bottom 0.30 to 0.45 mm

Color

Product details

| Application | Large Warehouses,General Food processing Industry,Pharmaceutical Industry |

| Core Thickness | 50 mm,75mm,100mm,120mm,150 mm |

| Foam Density | 40 kg/m3 |

| Length | 4-10 m |

| Surface Treatment | Galvanised,Coated |

| Features | Corrosion Resistant |

| Technique | Cold Rolled |

Outstanding Thermal and Acoustic Efficiency

Engineered for high-performance insulation, these panels maintain interior comfort by minimizing heat transfer and attenuating unwanted noise. The advanced PU core and precision-formed steel surfaces work together for excellent energy conservation and acoustic absorption, delivering sustainable solutions for diverse building environments.

Versatile Applications Across Industry Sectors

From warehouses and factories to shopping complexes and homes, these insulated metal panels provide reliable roofing and cladding. Their customizable sizing, multiple surface finishes, and robust mechanical strength make them ideal for new constructions and retrofits in residential, commercial, and industrial projects.

Durable, Maintenance-Free Performance

With high corrosion resistance, fire ratings up to international Class A/B standards, and a water absorption rate below 2%, these panels are designed for long service life. The use of pre-painted galvanized steel and advanced core materials ensures the panels resist weather, impact, and chemical exposure, reducing the need for maintenance.

FAQs of Metal Sheet Insulated Panels:

Q: How are metal sheet insulated panels installed for optimal thermal and acoustic performance?

A: These panels are designed for simple installation using tongue and groove or overlap joint systems. This ensures tight, secure connections that minimize thermal bridging and sound transmission, providing optimal insulation and acoustic attenuation. The lightweight nature of the panels also facilitates quick lifting and placement on site.Q: What types of surface finishes and coatings are available on these insulated panels?

A: Customers can choose from smooth, corrugated, or embossed finishes. Surface coatings include polyester, PPGL, or PPGI, all of which provide enhanced durability, corrosion resistance, and aesthetic appeal. Custom color options such as blue, grey, white, and other shades are available as required.Q: When should metal sheet insulated panels be used in building construction?

A: These panels are ideal for use in any construction requiring thermal and acoustic insulation, such as industrial warehouses, commercial complexes, and residential buildings. They are suitable for both roofing and external/internal wall cladding across new builds and renovation projects.Q: Where are metal sheet insulated panels commonly applied?

A: Insulated panels are typically used in industrial facilities, commercial enterprises, cold storage units, and residential developments throughout India. Their high load-bearing capacity and weather resistance make them suitable for varied climates and locations.Q: What is the manufacturing process for these insulated panels?

A: The panels are produced by sandwiching a high-density polyurethane or polyisocyanurate foam core between layers of pre-painted galvanized steel sheets. This process, which ensures excellent bonding and even foam distribution, results in panels with uniform insulation and robust structural integrity.Q: What benefits do these panels offer over traditional construction materials?

A: Compared to conventional building materials, these panels provide superior fire resistance, thermal efficiency, sound insulation, and weatherproofing. They are maintenance-free, easy to install, lightweight, and highly durable, reducing overall construction time and lifecycle costs.Q: Can the size and configuration of panels be customized to suit specific project requirements?

A: Yes, panel length (up to 12,000mm), thickness (30100mm), width, joint type, surface finish, and color can all be tailored to meet unique project needs, ensuring seamless integration within any structural design.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Insulated Panels Category

Cement Based Sandwich Panels

Price 30 INR / Square Meter

Minimum Order Quantity : 1000 Square Meters

Application : Commercial and residential buildings

Product Type : Cement Based Sandwich Panels

Capacity : High loadbearing capacity

Color : Grey

Send Inquiry

Send Inquiry